No one wants to launch a satellite that will fail once in space. Building, testing, and launching a satellite is a long and complex process that can take several years to complete. Many challenges must be overcome along the way. So how did OQ Technology assemble, test, and launch its TIGER-2 satellite in only few months?

Thanks to nowadays technology, we are able to build small satellites, named “cubesats”, that allow to drastically lower cost, reduce risk and shorten schedules. Cubesats are a standardized shape and size small satellites. The standard “cubesat unit”, referred as 1U, is a 10 cm cube with a mass of approximately 1.33 kg. Cubesats provide all the necessary subsystems needed for a space mission (on-board computer, power supply and management, communication, attitude and orbit control), and offer sufficient volume inside to carry one or more payloads. Cubesats allow to design and launch faster, better, and cheaper space missions.

One month ago, OQ Technology was launching TIGER-2, its first commercial 5G IoT satellite, and here is the story of its journey to space.

Developing TIGER-2: Materialize An Idea

Everything starts with an idea: At the time of the 5G development and the always growing demand of internet connectivity worldwide, the creation of new communication systems is more than ever a key element for the growth of the global economy. Especially in remote areas where limited coverage and insufficient communication infrastructures (e.g. cell towers) are a serious drawback and break to the attractivity of those regions. OQ Technology is planning to disrupt the communication industry by establishing a constellation of small satellites all around the Earth to link connected devices (i.e. Internet-of-Things) thanks to its innovative technology. It will allow a highly scalable, low cost, low power, and extremely secure communication network.

The payload components are firstly made as “Engineering Model” (EM). Basically, those EMs have the similar mechanical, electrical and thermal interfaces, as well as same functionalities as the “Flight Model” (FM), with the exception that they will remain on Earth. Their use is dual: having identical mechanical interface as the FM, they can be mechanically tested individually (vibrations, shock, thermal vacuum…); having identical functionalities, they can be used to ensure that each payload component perfectly fulfill its duty independently and once interconnected altogether to form the payload.

The next step is to connect the EM payload to an EM satellite, called “flatsat”. A flatsat is a replica of the actual satellite, but again, it is made to remain on Earth. It includes all the major subsystems (on-board computer, power supply and management, communication, attitude and orbit control), and its purpose is to help develop and test the payload software. Hence, it permits to verify the compatibility and interoperability between the payload and all the satellite subsystems.

The payload EM and flatsat are an important step in the development of a space mission. They enable to discover early and fix many potential issues that could endanger the mission once in space. They provide a real opportunity to validate, refine and improve the design of the payload hardware and software. Once this prototyping phase is finalized, the manufacture and assembly of the FM payload and satellite can begin.

Assembling TIGER-2: Built To Succeed

Assembling a satellite is a tense procedure that can rapidly become perilous. Indeed, thousands of tiny pieces with a specific purpose, each being more fragile than the others, must be placed at a precise location in the satellite. Every screw, bolts and nuts must be tightly attached to ensure the structural integrity of the satellite. Every cable and connection must be firmly plugged to guaranty power supply and data transfers.

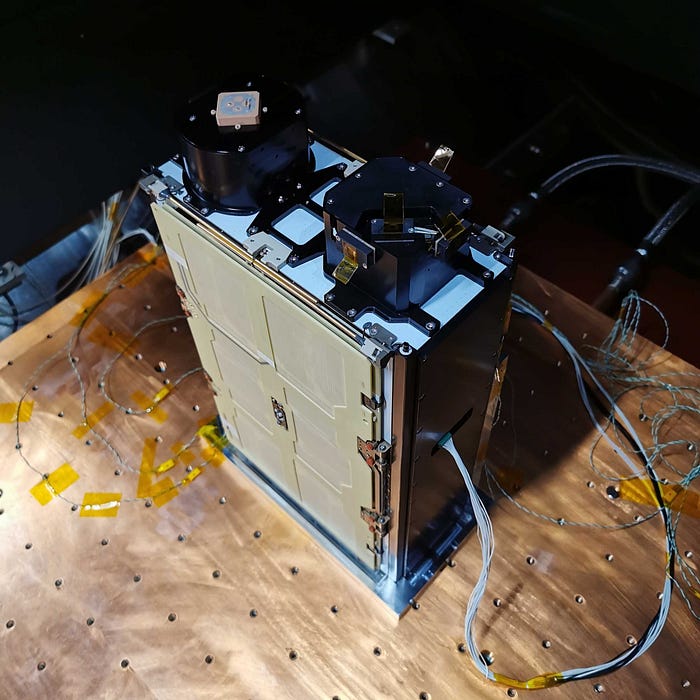

The OQ Technology communication payload needed a highly reliable platform able to deliver high power and very accurate attitude maneuvering capabilities. Thanks to our trusted partner NanoAvionics and its flight-proven 6U satellite bus including state-of-the-art subsystems, the OQ Technology payload found the perfect satellite platform to achieve high performance operations.

Testing TIGER-2: Survive The Worst Conditions

Once assembled, the satellite must go through a series of intense testing. There are two objectives: verify that the satellite was correctly assembled, and check that the satellite will survive both the harsh conditions experienced during the launch (vibrations, shocks), and the extreme environment of space (extreme temperatures, vacuum, radiations).

Therefore, TIGER-2 had to successfully pass each “environmental test” to be qualify ready to flight and allowed to go to space. TIGER-2 was tested in specific laboratories that are able to simulate the extreme vibration and shock levels experienced during the launch ascension phase. In fact, those tests were designed to replicate even higher levels to totally ensure the survivability of the satellite.

Besides, TIGER-2 passed a thermal vacuum test within which the satellite was literally baked in a dedicated thermal chamber to check its behavior when exposed to the severe space environment (extreme temperatures and vacuum). The satellite also went through Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) tests to ensure that the satellite would pose no harm to other spacecrafts or the launch vehicle by radiating unintentional RF emissions while integrated in the rocket.

Between each environmental test, TIGER-2 was tested functionally, to confirm that all satellite subsystems and the payload were still alive and fully operational. Additionally, at the end of the test series, a final “end-to-end” test was successfully performed to realistically simulate the space links (including free space loss), and hence validate mission operability. This test involved the OQ Technology communication payload integrated into the satellite, an OQ Technology ground-based terminal, and a simulated ground station. The payload antennas on the satellite were used to collect data from the ground-based terminal. The data were then processed by the payload on-board the satellite, and stored in the internal storage system, before being downloaded directly through the satellite S-band transceiver to the simulated ground station. This final end-to-end test contributed to successfully verify the operability of the satellite and payload over several simulated orbits. TIGER-2 was hence ready to move to the next phase, the integration into the cubesat deployer in preparation of the launch.

Launching TIGER-2: A New Rising Star

TIGER-2 was shipped to our partner launch partner Spaceflight Inc. to proceed with integration activities. The first step was to perform a satellite and payload health checkup to ensure that the shipment went smooth and did not damaged the satellite. Then, the satellite was integrated into the cubesat dispenser by OQ Technology and NanoAvionics teams. Cubesat dispensers have an important role during the launch phase, they serve as interface between the cubesat and the launch vehicle. A dispenser provides attachment to the rocket, protection during the launch, and is in charge to release the cubesat into space at the desired time. Finally, in the cubesat dispenser was itself integrated on the Spaceflight’s Sherpa LTE-1 module, an Orbital Transfer Vehicle (OTV) carrying multiple satellites (including Tiger-2). An OTV can be considered as a “space taxi”, carrying the satellite on the last kilometers before its release into space.

On the 30th of June 2021, OQ Technology launched its TIGER-2 satellite from Cape Canaveral (Florida — USA) aboard the SpaceX Transporter-2 rideshare mission organized by Spaceflight Inc. About an hour and a half following lift-off, Spaceflight’s Sherpa LTE-1 vehicle separated from the Falcon 9 upper stage and started the sequential deployment of the different satellites it was transporting. OQ Technology team received the confirmation that TIGER-2 was successfully ejected from the cubesat dispenser into space.

Few hours later, the OQ Technology and NanoAvionics teams acquired beacon signals emitted from Tiger-2 using their ground station located in Lithuania. Preliminary telemetry showed that the satellite system start up went as planned, the solar panels and antennas were well deployed, and that the satellite was in good health (nominal temperature and power levels). The following weeks were dedicated to Launch and Early Orbit Operations (LEOP). It included platform and payload commissioning. This phase is crucial to ensure that both the satellite and payload are entirely and perfectly operational. Hence, every subsystem is carefully verified to detect any potential malfunction following launch event. At the end of this phase, TIGER-2 will start providing commercial 5G IoT services worldwide.

Cyril Picavez

Space System Engineer at OQ Technology

Launch Video: